5 Tips Offset Printing

Introduction to Offset Printing

Offset printing is a widely used printing technique in which the inked image is transferred from a plate to a rubber blanket, then to the printing surface. This method is commonly used for high-volume printing jobs, such as newspapers, magazines, and brochures, due to its high speed and efficient production. In this article, we will discuss 5 tips for offset printing to help you achieve the best results.

Tip 1: Choose the Right Paper

The type of paper used can greatly affect the final result of your offset printing job. Coated papers are ideal for images with high contrast and vibrant colors, while uncoated papers are better suited for text-heavy documents. Consider the thickness and finish of the paper, as well as its brightness and opacity. The right paper can enhance the overall appearance of your printed materials and ensure they last longer.

Tip 2: Optimize Your Design

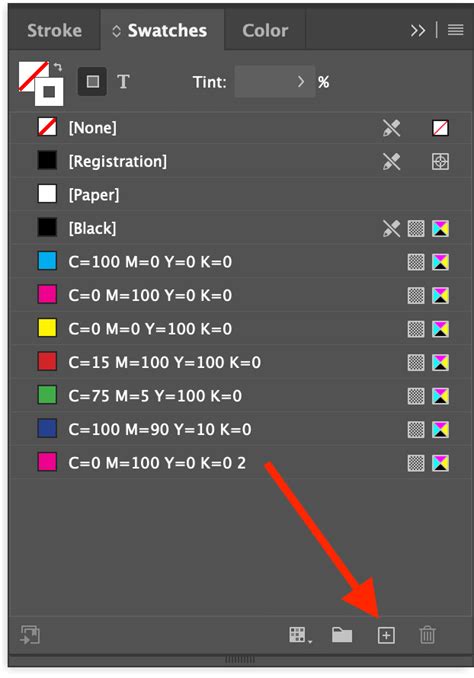

To get the most out of offset printing, your design should be optimized for the process. This includes using CMYK color mode instead of RGB, as CMYK is the standard color model for printing. Additionally, font sizes and line widths should be sufficient to ensure readability. It’s also important to consider the bleed and trim areas to avoid any crucial elements being cut off during the printing process.

Tip 3: Use High-Quality Images

The quality of your images can make or break the effectiveness of your printed materials. High-resolution images (at least 300 DPI) are essential for clear and sharp prints. Image compression should be avoided, as it can reduce the image quality. Furthermore, color correction is crucial to ensure the colors in your images are accurate and consistent with your brand.

Tip 4: Consider Special Finishes

Offset printing allows for various special finishes that can enhance the appearance and durability of your printed materials. Spot varnishing and aqueous coating can protect your prints from scratches and fading, while foil stamping and embossing can add a touch of luxury and sophistication. Consider the purpose and target audience of your prints to choose the most suitable finish.

Tip 5: Proofread and Review

Before sending your files to print, it’s essential to proofread and review them carefully. Check for any typos, grammatical errors, and formatting issues. A soft proof can help you preview how your prints will look, allowing you to make any necessary adjustments before the final print run.

📝 Note: Always ask for a hard proof or a press proof to ensure the final result meets your expectations.

To summarize, offset printing is a complex process that requires attention to detail and careful planning. By choosing the right paper, optimizing your design, using high-quality images, considering special finishes, and proofreading and reviewing your files, you can achieve professional-looking results that meet your needs and budget.

What is the difference between CMYK and RGB color modes?

+

CMYK (Cyan, Magenta, Yellow, and Key/Black) is the standard color model for printing, while RGB (Red, Green, and Blue) is used for digital displays. CMYK produces a wider range of colors and is more suitable for printing.

How do I choose the right paper for my offset printing job?

+

Consider the thickness, finish, brightness, and opacity of the paper, as well as the purpose and target audience of your prints. Coated papers are ideal for images with high contrast and vibrant colors, while uncoated papers are better suited for text-heavy documents.

What is the minimum resolution required for offset printing?

+

The minimum resolution required for offset printing is 300 DPI (dots per inch). High-resolution images ensure clear and sharp prints.